PHOTO: LRMC and DOST-MIRDC Executives during the E-Signing Ceremony

Sharing their knowledge in commercial business management and expertise in technical operations and development, respectively, the Light Rail Manila Corporation (LRMC) and the Department of Science and Technology – Metals Industry Research and Development Center (DOST-MIRDC) have entered into a new partnership to create a more efficient rail system that would make mobility and transportation better for Filipinos.

In a memorandum of understanding signed by both parties on 21 April 2021 in a virtual signing ceremony, LRMC and DOST-MIRDC have agreed to perform specific functions to achieve a common goal of sustaining the improvements in the Light Rail Transit Line 1 (LRT-1) system.

As the current private operator of LRT-1, LRMC is seeking the expertise of the DOST-MIRDC in conducting structural repairs of specific light rail vehicles (LRVs), as well as the local re-engineering and/or fabrication of spare parts that are already obsolete and/or difficult to source. Being the government agency tasked to foster the advancement of metals, engineering, and allied industries in the Philippines, the DOST-MIRDC is equipped with a wide range of capabilities that may be of further assistance to the LRMC in achieving more sustainable operations of the LRT-1.

“LRT-1 is a valuable mode of transportation for Filipinos in Metro Manila. We believe that with the expertise of our partners at DOST-MIRDC, we can continue enhancing the LRT-1 system to achieve our vision of becoming the commuter’s choice in transportation. Innovation and commitment to excellence are two of our company’s core values that allowed our management to implement best practices in public transport. Through this partnership, we hope to bring to the table our management expertise, as well as promote Filipino ingenuity by banking on the competence of our local talents,” says Enrico R. Benipayo, LRMC Chief Operating Officer.

LRMC’s partnership with DOST-MIRDC will bring the company to a new level of understanding in terms of various diagnostics equipment and technology that are not normally acquired by railway operators. It will provide the advantage of having an extended railway laboratory similar to other countries.

“Over the past few years that the LRMC has been taking charge over the LRT-1, we noticed the determination and commitment to improve the rail system and make everything efficient and convenient, especially for the Filipino commuting public. We appreciate the LRMC for trusting and believing in the capabilities and expertise of the DOST-MIRDC. We are proud to be part of the LRMC’s initiative to make public transportation more efficient. An improved rail system will not only benefit the commuting public; it will open doors of opportunities for various industries. This partnership is also a practical way for us to bring the benefits of science, technology, and innovation to the local metals, engineering, and allied industries,’ says DOST-MIRDC’s Executive Director, Engr. Robert O. Dizon.

Briefer on the DOST-MIRDC technology for LRMC

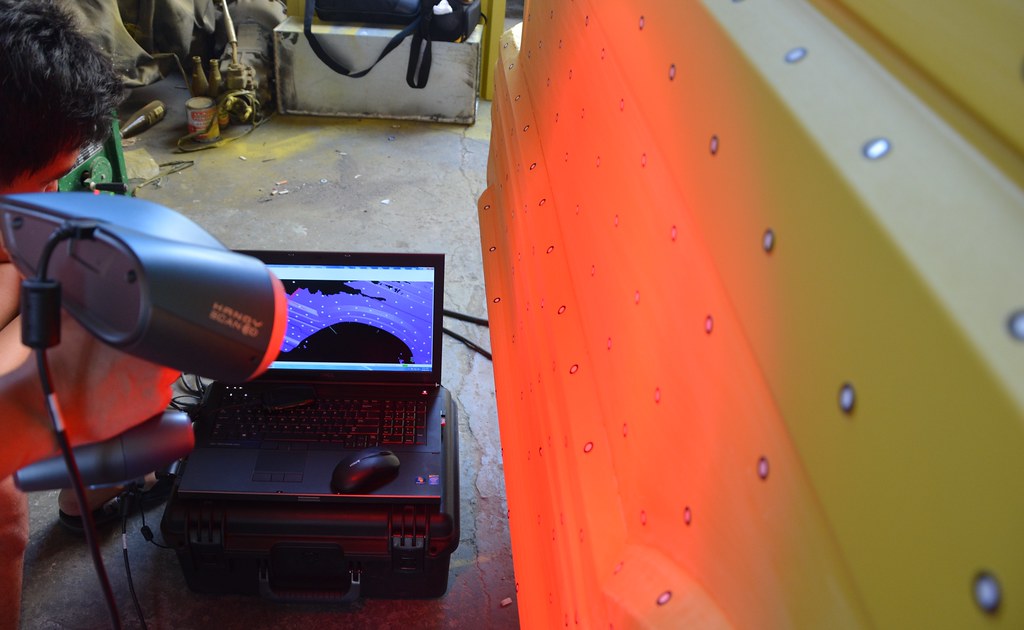

A. Non-Destructive Testing (NDT) : It is an inspection method to evaluate the integrity of materials, parts, or components while maintaining their usefulness.

1. Ultrasonic Testing Machine uses sound energy that is made to travel inside the material being tested. The sound energy sends different signals and the images are used to analyze the material’s integrity as well as measure its thickness.

Ultrasonic Testing Machines will allow the team to perform an internal assessment of the structural members of LRT-1 trains. It will allow to see if there are internal flaws (cracks or bubbles) on the structural frames to help in the decision-making whether to re-use or reject.

2. Radiographic Testing Using X-Ray Machine generates radiographic image which is used to analyze the material’s integrity. This is also a non-destructive testing method. Same use case as item 1 above. This also allows internal assessments of irregularly-shaped metals. Think of this as an x-ray machine for metals.

B. Laser Interferometer System for Dimensional Measurement : It serves as a reference standard for the calibration of line standards. It is used to determine linear positioning error of machines, pitch and yaw of machines, geometrical properties of the machine’s axes, and surface plate flatness. This technology will allow to test the rotational axis of machine after re-engineering. This will be vital for the acceptance of any re-engineered spares that are subject to rotary movement.

C. Finite Element Analysis (FEA) : A method used in solving stress-strain relationship in structures and solid bodies. Computer simulation allows multiple ‘what-if’ scenarios to be tested quickly and effectively. FEA involves 3D scanning, 3D printing, and rapid prototyping. This will be used to simulate stress points in any design. This will also help in analyzing and identifyung structural weaknesses prior to production.